S.G Enterprises has been a trusted name in the manufacturing and supply of high-quality industrial nuts since 1996. Founded by Mr. Jaswant Singh, the company has built a strong reputation for delivering precision-engineered fasteners that meet industry standards.

With decades of experience, we specialize in producing a wide range of industrial nuts designed to ensure durability, strength, and reliability for various applications. Our commitment to quality and innovation has made us a preferred partner for industries such as automotive, construction, machinery, and engineering. Our products are highly regarded for their exceptional strength, superior finish, corrosion resistance, long-lasting durability, and precise dimensions. These qualities make them a preferred choice in the market. We offer a wide range of specifications and provide customization options to meet our clients' specific requirements.

In today's fast-paced world, efficiency is key. We ensure rapid delivery to keep your business moving without delays.

Our team of seasoned professionals is dedicated to enhancing your brand’s presence with expert insights and tailored solutions.

We take pride in offering bespoke products tailored to your unique needs—options you won’t easily find elsewhere.

With a comprehensive selection under one roof, we cater to diverse industries across the globe.

Enjoy premium quality at cost-effective rates. We offer flexible pricing structures to meet your specific budget and accept multiple payment options.

Every project begins with a meticulous review of client specifications, ensuring seamless execution from concept to completion.

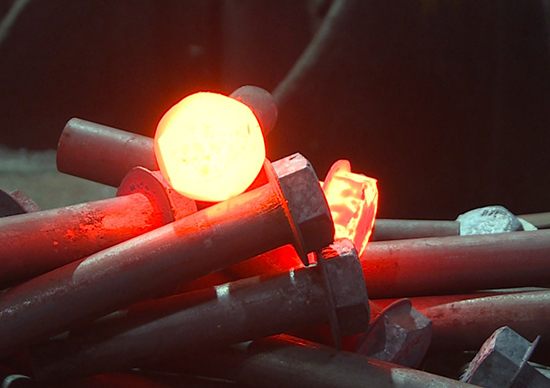

Hot forging is a metal shaping process that involves heating metal to a temperature above its recrystallization point before applying pressure to form the desired shape. This method is widely used in various industries due to its ability to enhance material properties and produce high-strength components.